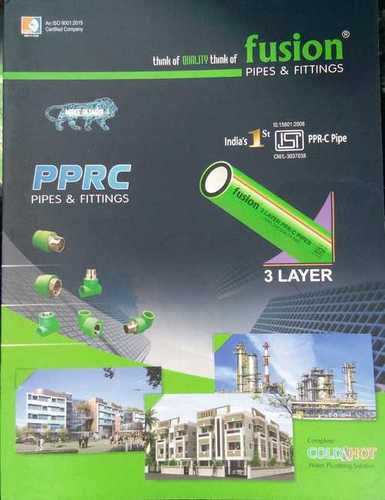

Fusion PPR Pipes

Fusion PPR Pipes Specification

- Flexibility

- Rigid

- Tolerance

- 0.2 mm

- Yield Strength

- > 20 MPa

- Diameter

- 20 mm, 25 mm, 32 mm, 40 mm, 50 mm, 63 mm, 75 mm, 90 mm, 110 mm, 160 mm

- Coating Type

- Uncoated

- Bend Radius

- Not recommended for bending

- Temperature Range

- -20C to +95C

- Sealing Type

- Thermal fusion, leak-proof

- Connection Type

- Fusion Joint

- Thread Type

- N/A (Threaded fittings available separately)

- Tensile Strength

- > 20 MPa

- Product Type

- PPR Pipe

- Material

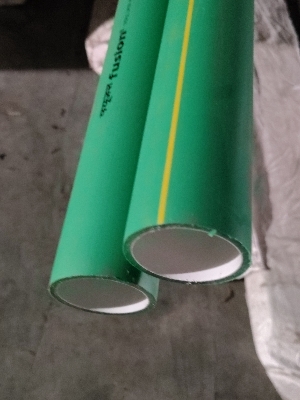

- Polypropylene Random Copolymer (PPR)

- Connection

- Socket Fusion, Butt Fusion, Electro Fusion

- Shape

- Round

- Standard

- DIN 8077/8078

- Surface Treatment

- Smooth

- Outer Diameter

- 20 mm to 160 mm

- Section Shape

- Circular

- Length

- 4 meters (standard), other lengths available on request

- Thickness

- From 1.9 mm to 13.7 mm

- Color

- Green

- Usage

- Cold and hot water supply systems

- Rated Pressure

- PN 10, PN 16, PN 20, PN 25

- Material Grade

- PPR Type 3

- Application

- Plumbing, Water Supply, Industrial Piping

Fusion PPR Pipes Trade Information

- Minimum Order Quantity

- 100 Meter

- Supply Ability

- 25 Per Day

- Delivery Time

- 1 Week

About Fusion PPR Pipes

Fusion PPR pipes are a type of plastic piping system known for their versatility durability and ease of installation Heres a detailed overview of Fusion PPR pipes

PPR Material

1 Polypropylene Random Copolymer PPR Fusion PPR pipes are made from PPR which is a type of thermoplastic polymer known for its high strength heat resistance and chemical inertness

2 Properties

Heat Resistance PPR pipes can withstand high temperatures making them suitable for both hot and cold water applications

Chemical Resistance They are resistant to corrosion and chemical degradation ensuring longevity and reliability in various environments

Smooth Interior PPR pipes have a smooth inner surface which reduces friction and prevents scaling or clogging

Fusion Welding

1 Jointing Technique Fusion PPR pipes are typically joined using a technique called heat fusion or fusion welding

Heat Fusion This involves heating the ends of the pipes and fittings to a specific temperature then pressing them together to create a seamless and strong joint

Advantages Fusion welding creates joints that are leakproof and maintain the integrity of the pipe system over time

Applications

1 Water Supply Fusion PPR pipes are commonly used for both residential and commercial water supply systems including potable water distribution

2 Heating Systems They are suitable for use in heating systems including underfloor heating due to their heat resistance and durability

3 Industrial Applications Fusion PPR pipes are also used in industrial applications for conveying chemicals compressed air and other fluids where resistance to corrosion and chemical attack is required

Advantages

1 Ease of Installation Fusion PPR pipes are lightweight and easy to handle facilitating quick and efficient installation

2 Longevity They have a long service life and require minimal maintenance reducing lifecycle costs

3 Environmental Impact PPR pipes are recyclable and environmentally friendly contributing to sustainable building practices

4 Versatility They can be used in a wide range of temperatures and applications without compromising performance

Considerations

1 Cost While initial costs may be higher compared to some traditional materials the longterm benefits of durability and low maintenance often outweigh the initial investment

2 Installation Skills Fusion welding requires trained personnel to ensure proper jointing and system integrity

In summary Fusion PPR pipes are valued for their robustness chemical resistance and ease of installation using heat fusion techniques They are widely adopted in plumbing and industrial applications where reliability and longevity are paramount

Exceptional Chemical and Corrosion Resistance

Fusion PPR Pipes offer high resistance to a multitude of chemicals and are completely corrosion-free. This feature ensures the longevity and durability of piping installations, making them a reliable choice for water supply and industrial environments with aggressive substances.

Quick and Secure Installation Process

These pipes utilize advanced thermal fusion welding, which allows for rapid and homogenous joint formation without the risk of leakage. The fusion technique guarantees strong, reliable connections, reducing installation time and ensuring seamless system integrity.

Eco-Friendly and Hygienic Solution

Made from recyclable PPR Type 3 material, Fusion PPR Pipes support sustainable building practices. Their food-grade quality ensures suitability for potable water systems, while the low internal roughness minimizes pressure loss and promotes hygienic water transportation.

FAQ's of Fusion PPR Pipes:

Q: How are Fusion PPR Pipes installed for leak-proof performance?

A: Fusion PPR Pipes are installed using thermal fusion welding methods such as socket fusion, butt fusion, or electro fusion. This process creates a homogeneous bond between pipe joints, ensuring a completely leak-proof system that is ideal for both residential and industrial applications.Q: What makes Fusion PPR Pipes suitable for potable water supply?

A: These pipes are manufactured from food-grade Polypropylene Random Copolymer, ensuring they are safe for conveying potable water. Their smooth, non-reactive surface prevents contamination and supports hygienic water supply in compliance with international standards.Q: When should UV protection be considered for these pipes?

A: Fusion PPR Pipes have medium UV resistance and are primarily recommended for indoor use. If installation outdoors is necessary, additional protective measures such as UV-resistant coatings or covers should be considered to preserve pipe integrity.Q: Where can Fusion PPR Pipes be used?

A: They can be employed in a variety of indoor settings, including residential plumbing, hot and cold water supply systems, and industrial piping for chemical transport, thanks to their chemical resistance, leak-proof joints, and corrosion-free construction.Q: What are the environmental benefits of using Fusion PPR Pipes?

A: These pipes are fully recyclable and made from eco-friendly materials, minimizing their environmental impact during their lifecycle. Their durability reduces replacement frequency, contributing to sustainable water management.Q: How does the pipe's low internal roughness benefit water systems?

A: The smooth internal surface minimizes pressure loss and prevents deposits within the piping system. This ensures excellent flow rates in plumbing and industrial applications, enhancing overall efficiency and reducing maintenance demands.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in PPRC PIPES FITTINGS Category

PPRC Pipes Fittings

Price 238 INR / Meter

Minimum Order Quantity : 100

Application : other, Plumbing, Drinking Water, Industrial Liquid Conveyance

Shape : Round

Material : Other

Connection : Butt Fusion

Pprc pipes

Price 10000 INR / Meter

Minimum Order Quantity : 100

Application : Structure Pipe

Shape : Round

Material : Non metalic

Connection : Socket Joint

PPRC Pipes

Price 400.0 INR / Number

Minimum Order Quantity : 10

Application : Industrial

Shape : Round

Material : Stainless Steel

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese