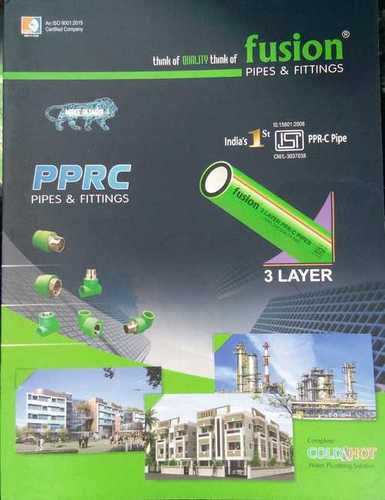

PPRC Pipes

Price 400.0 INR/ Number

PPRC Pipes Specification

- Usage

- Construction

- Application

- Industrial

- Material Grade

- A

- Surface Finish

- Polished

- Product Type

- PPRC Pipes

- Material

- Stainless Steel

- Shape

- Round

PPRC Pipes Trade Information

- Minimum Order Quantity

- 10 Number

- FOB Port

- Hazira,Bhavnagar

- Payment Terms

- Cash Against Delivery (CAD), Cash in Advance (CID)

- Supply Ability

- 1000 Per Day

- Delivery Time

- 7 Days

- Packaging Details

- As per requirement

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Africa, Middle East

- Main Domestic Market

- All India

- Certifications

- ISO CERTIFIED

About PPRC Pipes

It appears that you're asking about PPRC pipes. PPRC stands for "Polypropylene Random Copolymer" pipes, which are a type of plastic piping system used for various applications, including plumbing, heating, and cooling. Here's some information about PPRC pipes:

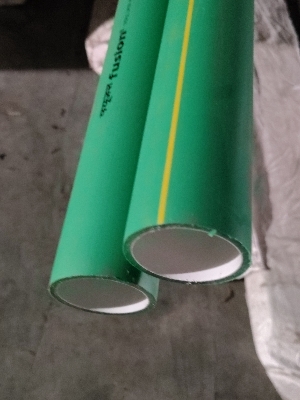

Material: PPRC pipes are made from a type of thermoplastic polymer called polypropylene random copolymer. This material is known for its excellent properties, such as high-temperature resistance, corrosion resistance, and durability.

Applications: PPRC pipes are commonly used in residential and commercial buildings for plumbing and heating systems. They are suitable for carrying both hot and cold water, making them versatile for various plumbing needs.

Advantages:

- High Temperature Resistance: PPRC pipes can withstand high-temperature water and steam, making them suitable for hot water distribution systems.

- Corrosion Resistance: They are highly resistant to corrosion and chemical reactions, ensuring a long lifespan.

- Low Thermal Conductivity: PPRC pipes have low thermal conductivity, which helps in maintaining the temperature of the water being transported.

- Lightweight: They are relatively lightweight compared to some other piping materials, which makes installation easier.

- Low Maintenance: PPRC pipes require minimal maintenance over their lifespan.

- Installation: PPRC pipes are typically joined using heat fusion welding, which creates a strong and leak-resistant connection. This process involves heating the pipe and fittings to their melting point and then fusing them together. It's essential to follow the manufacturer's guidelines for proper installation.

- Disadvantages: While PPRC pipes offer many advantages, they can be more expensive upfront compared to some other piping materials. However, their durability and low maintenance costs can make them cost-effective in the long run.

PPRC pipes have gained popularity in many regions for their reliability and performance in plumbing systems. When considering PPRC pipes for your project, it's essential to consult with a plumbing professional to ensure they are the right choice for your specific needs and local building codes.

Superior Durability for Industrial Needs

Designed from top-grade stainless steel, these round PPRC pipes offer lasting performance in demanding construction and industrial environments. The polished surface enhances corrosion resistance and maintains structural integrity over years of usage.

Polished Finish Ensures Reliability

The smooth, polished surface of these pipes reduces accumulation of debris and facilitates easy cleaning, making them a prime choice for industrial processes requiring high hygiene and operational efficiency.

FAQ's of PPRC Pipes:

Q: How are PPRC pipes used in industrial construction projects?

A: PPRC pipes serve as reliable conduits for fluids and gases, and as structural components in industrial construction due to their strength and corrosion resistance. Their polished, round design ensures efficient installation and long-term functionality in harsh environments.Q: What benefits do stainless steel PPRC pipes with a polished finish offer?

A: The combination of stainless steel's durability and a polished finish leads to enhanced corrosion resistance, reduced maintenance, and improved longevity, benefiting industrial facilities by minimizing downtime and repair costs.Q: Where can I source high-grade PPRC pipes for my industrial project in India?

A: You can obtain these PPRC pipes from reputable suppliers and traders specializing in industrial materials across India, ensuring you receive quality products suited for demanding applications.Q: When should polished PPRC pipes be chosen over other material grades?

A: Polished Grade A stainless steel PPRC pipes are the optimal choice when your project demands superior corrosion resistance, aesthetic appeal, and structural reliability, particularly in environments exposed to chemicals or high moisture.Q: What is the process involved in installing round PPRC pipes in an industrial setting?

A: Installation typically involves careful measurement, aligning the pipes for optimal flow or structural support, securely joining sections using appropriate fittings, and routinely inspecting the polished surfaces to maintain performance.Q: How does the surface finish contribute to the usage efficiency of these pipes?

A: The polished surface finish minimizes friction and prevents debris accumulation, resulting in smoother fluid transport, easier cleaning, and more reliable operation in industrial processes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in PPRC PIPES FITTINGS Category

PPRC Pipes Fittings

Price 238 INR / Meter

Minimum Order Quantity : 100

Color : GREEN AND BLUE

Material : Other

Flexibility : High

Application : other, Plumbing, Drinking Water, Industrial Liquid Conveyance

Pprc pipes

Price 10000 INR / Piece

Minimum Order Quantity : 100 Pieces

Color : Green

Material : Non metalic

Application : Structure Pipe

PPRC Elbow 45

Price 154.0 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Green

Material : PVC

Flexibility : Rigid

Application : Construction

PPRC Equal Tee

Price 120.0 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Green

Material : PVC

Flexibility : No

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese