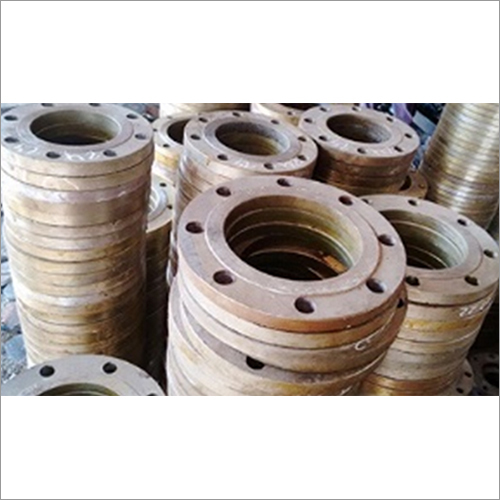

Industrial SS Flange

Price 300 INR/ Piece

MOQ : 1000 Pieces

Industrial SS Flange Trade Information

- Minimum Order Quantity

- 1000 Pieces

- FOB Port

- Hazira,Bhavnagar

- Payment Terms

- Cash Against Delivery (CAD)

- Supply Ability

- 100 Pieces Per Day

- Delivery Time

- 1 Week

- Main Export Market(s)

- Australia, South America

- Main Domestic Market

- All India

About Industrial SS Flange

Industrial SS flanges are components used in piping systems to connect pipes valves pumps and other equipment SS stands for stainless steel indicating that these flanges are made from stainless steel which is highly resistant to corrosion and oxidation

These flanges are crucial in industrial settings where the integrity and reliability of connections are paramount They come in various types and sizes to accommodate different pressure ratings and application requirements Common types of SS flanges include

1 Weld Neck Flanges These have a long neck that is welded to the pipe offering good strength and stress distribution

2 SlipOn Flanges These are slipped over the pipe and welded both inside and outside to provide sufficient strength and prevent leakage

3 Socket Weld Flanges These are designed for use with smaller size pipes and are connected by inserting the pipe into the socket end and applying fillet weld around the top

4 Threaded Flanges These flanges have threads inside and are used with pipes that have external threads They are not suitable for highpressure applications

5 Blind Flanges Used to close the end of a piping system or vessel opening providing easy access for inspection or cleaning

6 Lap Joint Flanges These are used with a stub end or a buttwelded flange They are primarily used for lowpressure applications

The choice of SS flange depends on factors such as the applications pressure temperature and corrosive environment Proper installation and maintenance of these flanges are crucial for ensuring the efficiency and safety of industrial piping systems

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in SS Flange Category

SS Sight Glass Flanged

Price 150 INR / Piece

Minimum Order Quantity : 100 Pieces

Application : Hydraulic Pipe

Product Type : SS Sight Glass Flanged, Other

Grade : As per Standard

Size : 25mm

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese